PRODUCTS

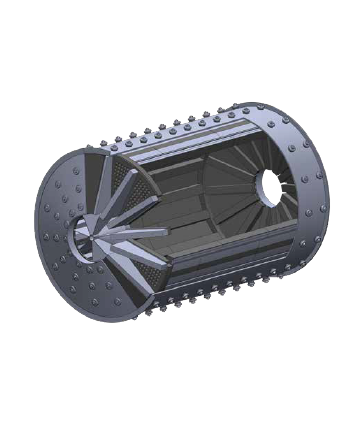

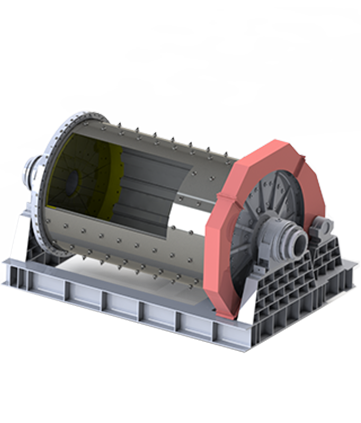

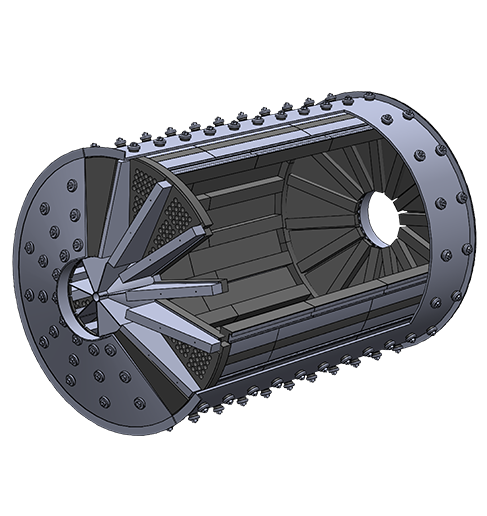

Mill Liners

Mill Liners

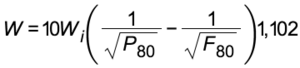

Basic Calculations for Rod and Ball Mills

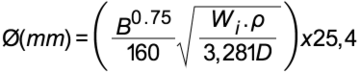

The first step to determine the size of the mill required is to calculate how many kilowatts of energy will be consumed per ton to grind the ore to the desired grain size. To do this, the following equation called the Bond Formula gives the energy to be consumed per ton of ore.

![]() = Work Index (an index that determines the grindability of the ore; different for each ore type. This value is approximately 7-9 for ores that are easily grinded and approximately 15-20 for ores that are difficult to grind.)

= Work Index (an index that determines the grindability of the ore; different for each ore type. This value is approximately 7-9 for ores that are easily grinded and approximately 15-20 for ores that are difficult to grind.)

![]() = Aperture of the screen through which 80% of the ground ore passes, micron.

= Aperture of the screen through which 80% of the ground ore passes, micron.

![]() = Aperture of the screen through which 80% of the ore to be fed to the mill passes, micron.

= Aperture of the screen through which 80% of the ore to be fed to the mill passes, micron.

![]() = Conversion factor to metric ton

= Conversion factor to metric ton

The energy requirement calculated by the formula above is the energy in the pinion shaft of the mill. It is necessary to add at least 10% to this as losses in motor, reducer and couplings.

In dry grinding, the energy requirement increases by about 30% due to elastic-plastic deformations (cushioning effect).

Therefore, it is necessary to multiply the above formula result by “1.30” in dry grinding.

Some Other Important Correction Factors:

Diameter: If the mill diameter is bigger or smaller than 2.44 m, it is corrected with:

D = grain size, micron

In addition to the above two correction factors, there are also correction factors such as open or closed circuit operation of the mills, size reduction ratio, and feed grain size. As long as no crushed ore larger than 25 mm is fed to the rod mill and no crushed ore larger than 10 mm is fed to the ball mill, the above information is sufficient to have an idea about the selection or accuracy of the motor power.

*These values may vary ± depending on the geological processes (alteration, microtectonic, etc.) that ores undergo.

First Charges of Mills:

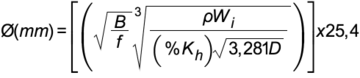

Using rods or balls with unnecessarily greater diameters will definitely decrease the grinding efficiency. The first charge is therefore very important. During the first charge, the rod or ball with the largest diameter can be calculated from the following formulas and the first charge is performed using the Charge Table. After the first charge, additions to the reduced charge due to wear are always performed at the largest diameter in the first charge.

Rod Charge:

![]() : Aperture of the screen through which 80% of the feed grain size passes, micron

: Aperture of the screen through which 80% of the feed grain size passes, micron

![]() : Specific gravity of the ore

: Specific gravity of the ore

![]() : Critical speed percentage, like 0.6, 0.65

: Critical speed percentage, like 0.6, 0.65

![]() : Mill diameter, meters

: Mill diameter, meters

![]() : Work (grindability) index

: Work (grindability) index

Table: Diameter-Weight % Relationship for Initial Rod Charge

W1 Values for Some Ores

Barite | 6.24 |

Bauxite | 9.45 |

Chrome Ores | 9.60 |

Copper Ores | 13.13 |

Feldspar (Orthoz) | 11.67 |

Feldspar (Albite) | 9.30 |

Hematite | 12.68 |

Magnetite | 10.21 |

Specularite | 15.40 |

Lead-Zinc | 11.35 |

Phosphate | 10.13 |

Quartz | 12.77 |

Quartzite | 12.18 |

Stream Gravel | 25.17 |

Lignite | 13.40 |

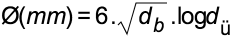

Ball Charge:

f = It is 350 if the ball mill is wet and open circuit, and it is 330 if it has diaphragm. It is 335 in dry grinding.

As an alternative to the above formula, the Olewski formula can be used.

db= Largest grain size in the feed, mm

dü = Largest grain size in the ground product, mm

Chart: Diameter-Weight % Relationship for Initial Ball Charge

Rod Diameter, mm | 125 | 115 | 100 | 90 | 75 | 65 |

125 | 18 | - | - | - | - | |

115 | 22 | 20 | - | - | - | |

100 | 10 | 23 | 20 | - | - | |

90 | 14 | 20 | 27 | 20 | - | |

75 | 11 | 15 | 21 | 33 | 31 | |

65 | 7 | 10 | 15 | 21 | 39 | 34 |

50 | 9 | 12 | 17 | 26 | 30 | 66 |

Total % | 100 | 100 | 100 | 100 | 100 | 100 |

Ball Diameter, mm | 115 | 100 | 90 | 75 | 65 | 50 | 40 |

115 | 23 | - | - | - | - | ||

100 | 31 | 23 | - | - | - | ||

90 | 18 | 34 | 24 | - | - | ||

75 | 15 | 21 | 38 | 31 | - | ||

65 | 7 | 12 | 20.5 | 39 | 34 | ||

50 | 3.8 | 6.5 | 11.5 | 19 | 43 | 40 | |

40 | 1.7 | 2.5 | 4.5 | 8 | 17 | 45 | 51 |

25 | 0.5 | 1.0 | 1.5 | 3 | 6 | 15 | 49 |

Total % | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

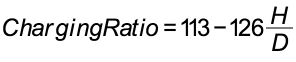

Filling Rates of the Mills

The mills should be filled with a suitable weight of rod or ball to benefit from most of the motor power.

Filling ratios are generally 30-35% of the mill volume in rod mills and 40-45% in ball mills.

Especially after rod charge, the charge swells up to 45% due to the coarse grain size (~25 mm) of the ore between the rods. Therefore, the charge is initially kept low. This effect is much less for the balls. When a running mill stops for different reasons from time to time, it can be entered through the "manhole" and the filling ratio can be found according to the following formula.

H = Height from charging surface to liner, meters

D = Mill diameter, meters

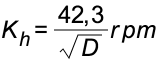

Critical Speed:

Rod mills are generally operated at 60-70% of the critical speed and ball mills at 70-80%. A speed greater than 70% can cause unnecessary wears and rod breakages in rod mills.

High speeds in ball mills are suitable for relatively coarse grinding.