Mill Liners

Mill Liners

Mill Liners

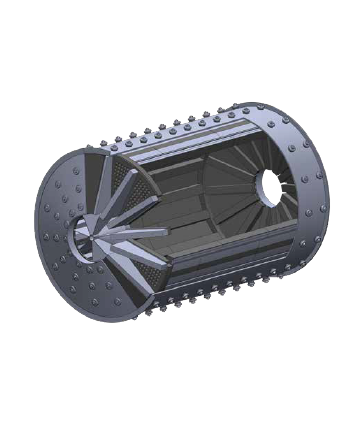

Tufekcioglu has been manufacturing rubber liners and lifterbars for rod, ball and autogenous mills and assembling its own production since 1982.

Rubber liners operating with great success in metal mining, ceramic industry, lime industry, industrial minerals, coal, sand-gravel, etc., industries are used in plants without any problems and with a long-term guarantee thanks to the special rubber formula developed with years of experience.

Liners and lifterbars are designed according to the technical data of the mill and the characteristics of the material to be milled, and are produced for all types of mills. Rubber liner life depends on its design as well as its quality. Tufekcioglu has proven its success with its liner designs and has been a brand preferred for years.

Compared to alternative materials such as steel and stone, rubber liners;

Specifications of Liners

- Quiet working environment

- Ease of initial assembly, replacement and maintenance

- Reduction in the number of mechanical failures and energy savings of 4-5% in milling by reducing the static load due to the lighter weight of the rubber liners

- Rubber liners do not have an abrasive effect on balls as in steel liners, and saving around 1.5% in ball consumption

Note for the User: In rod mills, rods should be checked in short periods. Otherwise, broken or sharp rods may break the rubber liner.

Alumina Rubber Liner

With this new design rubber liner, which renews itself for the ceramic industry, the grinding also takes place between the alumina ball on the liner surface and the liner, allowing the mill to operate more efficiently. It also reduces the energy consumption of the mill.

Since alumina balls are wear resistant, it has provided a significant extension in the life of the liner. These new design liners were laid on 17.04.2015 at the Vitra Karo factory in order to test a 38,000 lt mill and a successful result was obtained.